Design Optimisation

The aim of this project was to design and optimise the power output from a fan using a miniture turbine.

Skills Developed

- Large datasets

- Design optimisation techniques – simulations & experiements

- Principles of Fluid dynamics

Team Size

2

project Length

3 weeks

Year

2019

This project was an introduction to design optimisation. The short time period for this project meant relying of rapid simulations to produce a solution rather than a rapid prototyping cycle. Using Blade-Element-Momentum-Theory (BEMT) a simulation was created in Matlab and XFOIL, managing and comparing large datasets of aerofoils, that predicted the most effective blade profile for the fans output wind velocity.

Once the simulation was completed a program was created to translate the simulated blade profile into multiple co-ordinate points in excel. This enabled the creation of CAD struts allowing the physical design of the wind turbine. Experiments were then used to validate improve the physical design of the wind turbine

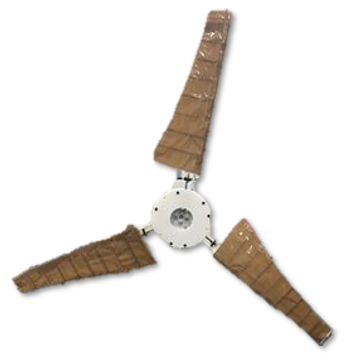

Final Turbine

The final turbine managed to spin at a rotational speed of 280 rpm. A co-efficient of power of 7%. Pretty good for a turbine made from wood, plastic and tape.

The weight distribution was slightly off causing the turbine to shake. Therefore in future optimisations the turbine would be balanced better enabling a higher rpm.